MIL Spec Connectors

At the core of MIL-Spec connectivity are circular connectors, and understanding their construction is fundamental when selecting the right connectors.

MIL-C-5015 MIL-C-26482 and VG95234 widely used in the field of industrial equipment.

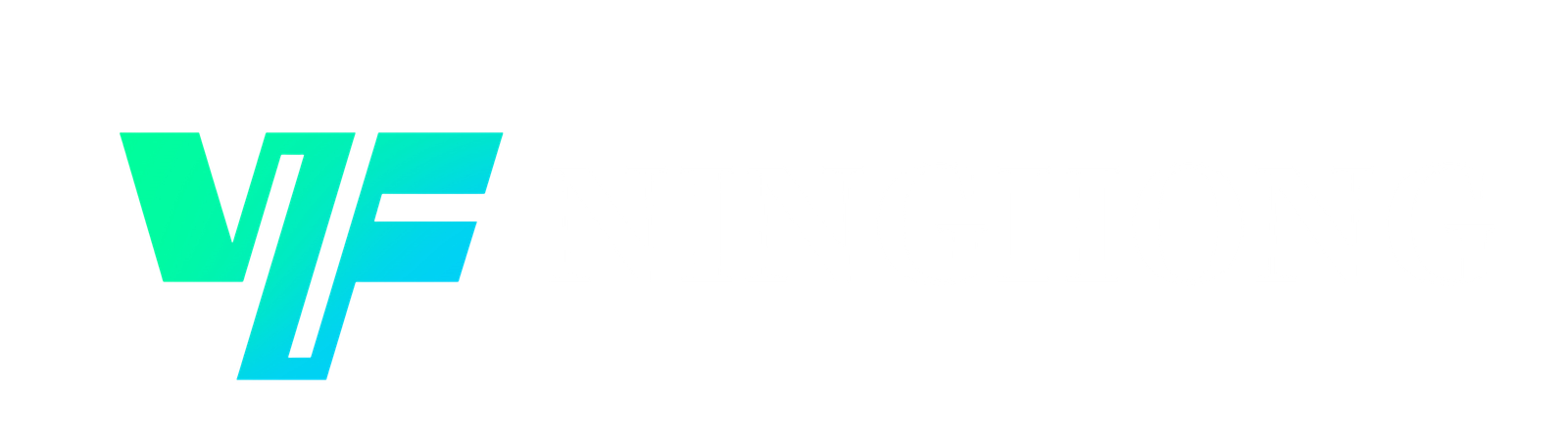

MIL-C-5015

- Due to its sturdy and durable characteristics, it is widely used in power and signal equipment in various fields.

- Welding type products that can be wired without the need for specialized tools, making it easy to carry out operations.

- Provide various types of products for users to choose from, including straight through, angled, panel mounted, and relay types.

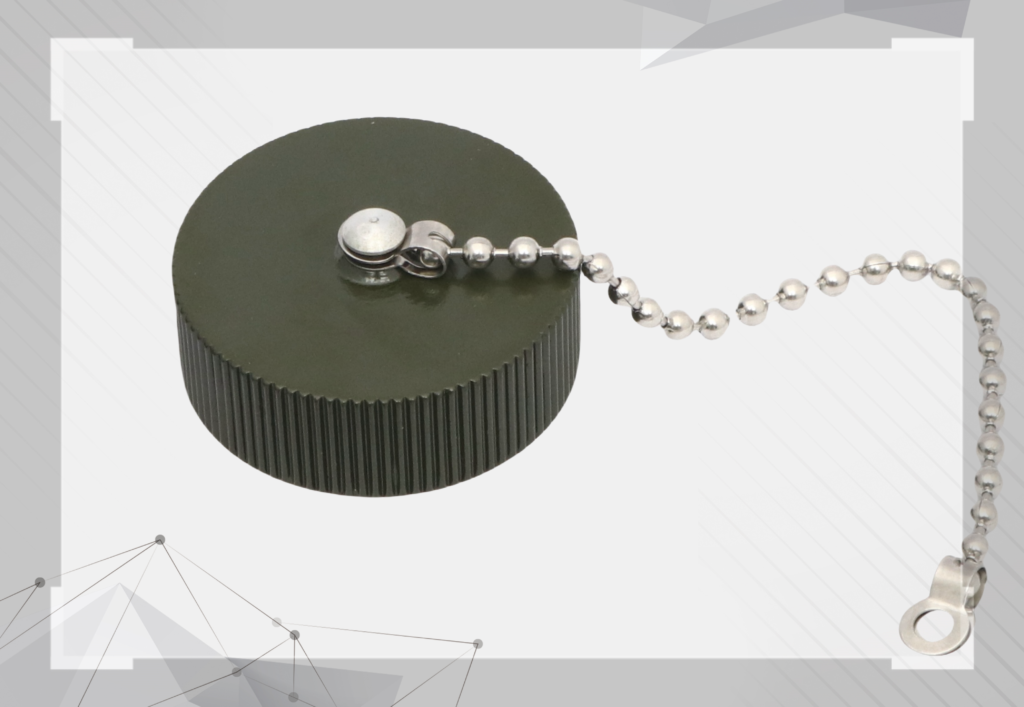

MIL-C-26482

- Widely used small connectors that meet general requirements for two series of environment-resisting, quick disconnect, and miniature circular connectors.

- 3-point bayonet coupling.

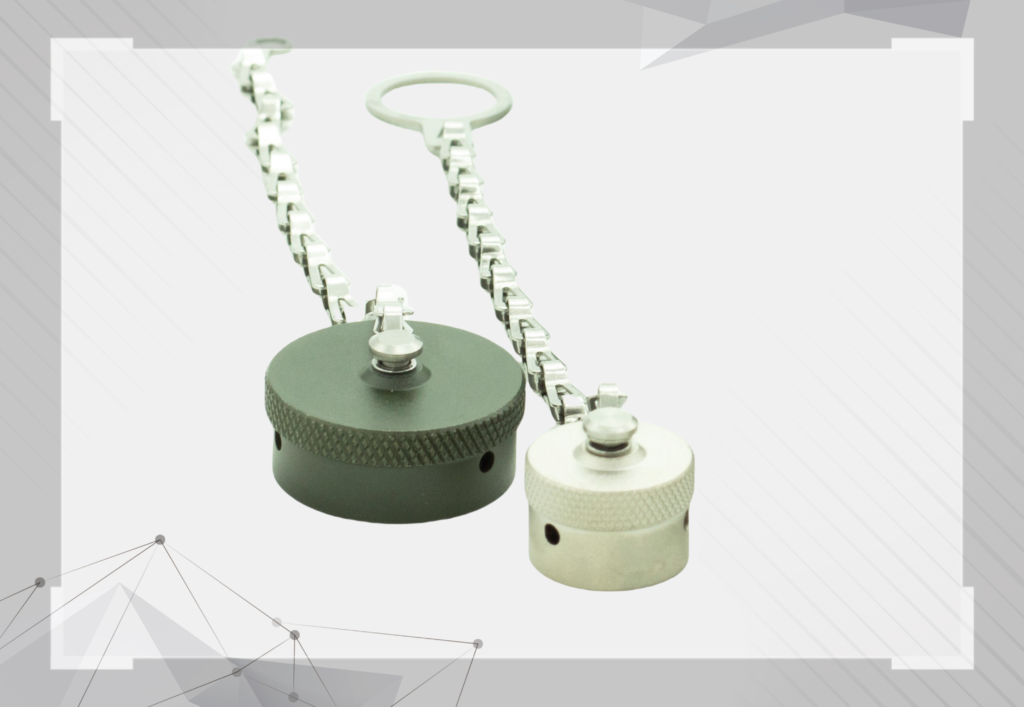

VG95234

- Adopting a snap on or reverse bayonet joint design ensures quick and easy locking and unlocking, while preventing accidental unlocking during severe vibrations. It has waterproof, anti vibration and other characteristics, suitable for harsh environments.

High Reliability

They have a sturdy structure that can work stably in harsh environments, maintaining high efficiency and performance

Strong Durability

They can maintain good performance in high-pressure, high-temperature, and corrosive environments.

Strong Stability

The connector is designed to reduce electromagnetic interference, ensuring the stability and accuracy of signal transmission.

Product Category

MIL-C-5015

MS3106A

MS3108A

MS3102A

MS3100A

MS3101A

25043

25042

Shell Size:

10SL

14S

16S

18

20

22

24

28

32

Essential Details

Material and spec

Coupling | Threaded |

Shell material | Aluminum alloy |

Insert material | TPU |

Contact material | Brass with gold plating and silvering plating |

Termination | weld:φ1.6、φ2.4、φ3.6、φ5.7 Solder: φ1.6、φ2.4、φ3.6、φ5.7 |

Mechanical life | 500 cycles |

Temperature range | -40℃-+70℃ |

VG95234

3106A

3108A

3102A

3100A

3101A

25043

Shell Size:

10SL

14S

16S

18

20

22

24

28

Essential Details

Material and spec

Coupling | Buckle |

Shell material | Aluminum alloy |

Insert material | TPU |

Contact material | Brass with gold plating and silvering plating |

Termination | weld:φ1.6、φ2.4、φ3.6、φ5.7 Solder: φ1.6、φ2.4、φ3.6、φ5.7 |

Mechanical life | 500 cycles |

Temperature range | -40℃-+70℃ |

MIL-C-26482

MS3116F

MS3112F

MS3181

Shell Size:

8

10

12

14

16

18

20

22

24

Essential Details

Material and spec

Coupling | Buckle |

Shell material | Aluminum alloy |

Insert material | Polychloroprene |

Contact material | Brass with gold plating |

Mechanical life | 500 cycles |

Temperature range | -55℃-+125℃ |

MIL Spec Connector Video

The video briefly demonstrates the production scenario of MIL Spec connectors and MIL-c-5015 connectors.

Basic Parameters

Material And Spec

Contacts OD |

|

|

|

|

| |

(AWG) | (mm) | Weir OD | wire Size (AWG) | Metric(mm²) | Conductor OD(mm) | Solder cup(mm) |

16 | φ1.6 | 1.6-3.3 | 20-16 | 1.3max | 1.25-1.70 | 1.7 |

12 | φ2.4 | 2.9-4.3 | 14-12 | 3.5max | 1.95-1.24 | 2.9 |

8 | φ3.6 | 4.2-6.5 | 10-8 | 8.0max | 4.3-4.8 | 5.2 |

4 | φ5.7 | 6.9-9.4 | 6-4 | 22.0max | 5.2-6.0 | 7.6 |

Medium Pressure

Grade | Dielectric withstand voltage | Operating voltage | |

Direct Current (DC)V | Alternating Current (AC)V | ||

Instument | 1000 | 250 | 200 |

A | 2000 | 700 | 500 |

D | 2800 | 1250 | 900 |

E | 3500 | 1750 | 1250 |

B | 4500 | 2450 | 1750 |

C | 7000 | 4200 | 3000 |

Attention: The arrangement of the instrument, A D E B C insulator holes should correspond to each other.

Chinese MIL Spec Connector Factory

- Minimum Order Quantity: 2 pieces per model.

- We can custom specific connector as per your demands.

- Delivery time: 3-7 days for small batch orders

How to Customize Connector

Collaborating with us not only provides advantages in product cost and quality, but also meets your customization requirements.

#1 Inquiry project

Kindly share your project prototype or ideas which type connector you will prepare to use.

#2 Evaluation & Sample

Your whole project will be evaluated and replied with the best connector solution with the arranged samples.

#3 Testing & Confirm

As soon as you receive the sample, you can conduct testing according to your requirements

#4 Production & Delivery

We will arrange mass production based on sample confirmation and specification, then ship by sea or express for your specific connectors.

Advantage

1.The factory has spare parts and finished products, which can be shipped quickly.

2.The cost control method is used as a management approach, which can efficiently control costs.

3.Each process undergoes employee self inspection, inspection, patrol, sampling, and full inspection, with quality control throughout the entire process.

4.We will ship daily according to customer requirements.

5.There is a VIP channel for salespeople in the factory management system, and urgent orders can be directly inserted and shipped on the same day.

6.Engineers can provide free product selection suggestions and design drawings for free.